Flinders Street Train Station Restoration 2016-2018

-

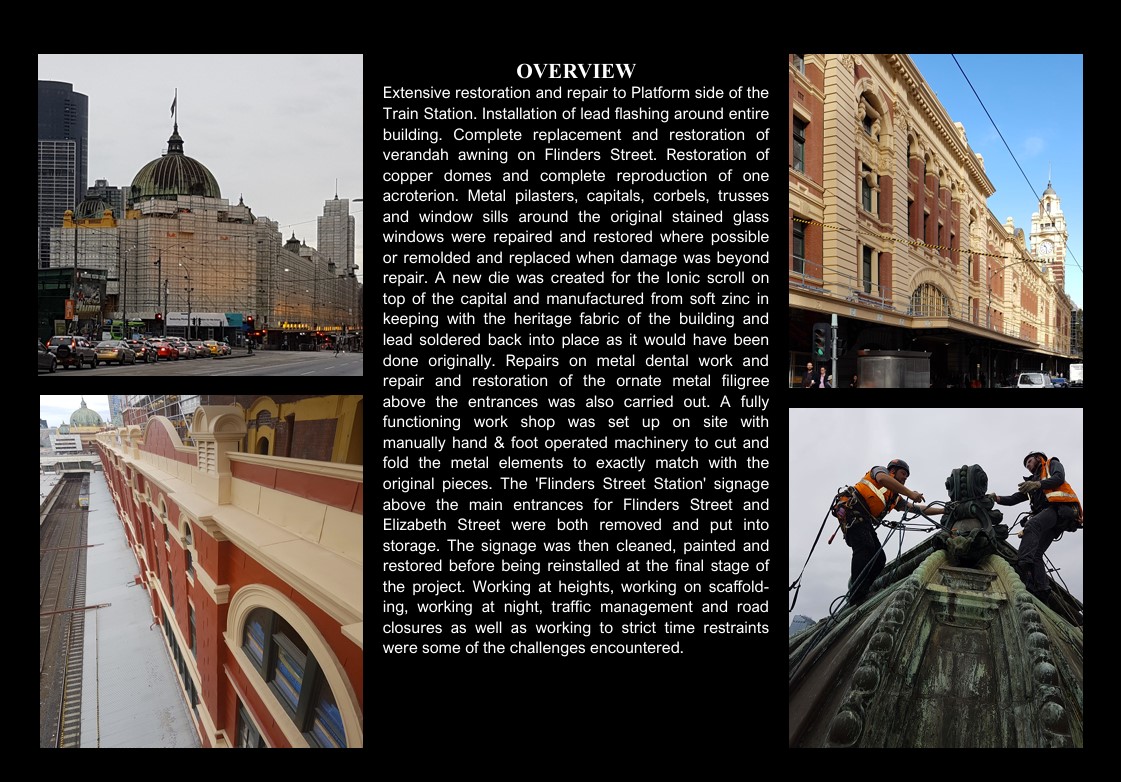

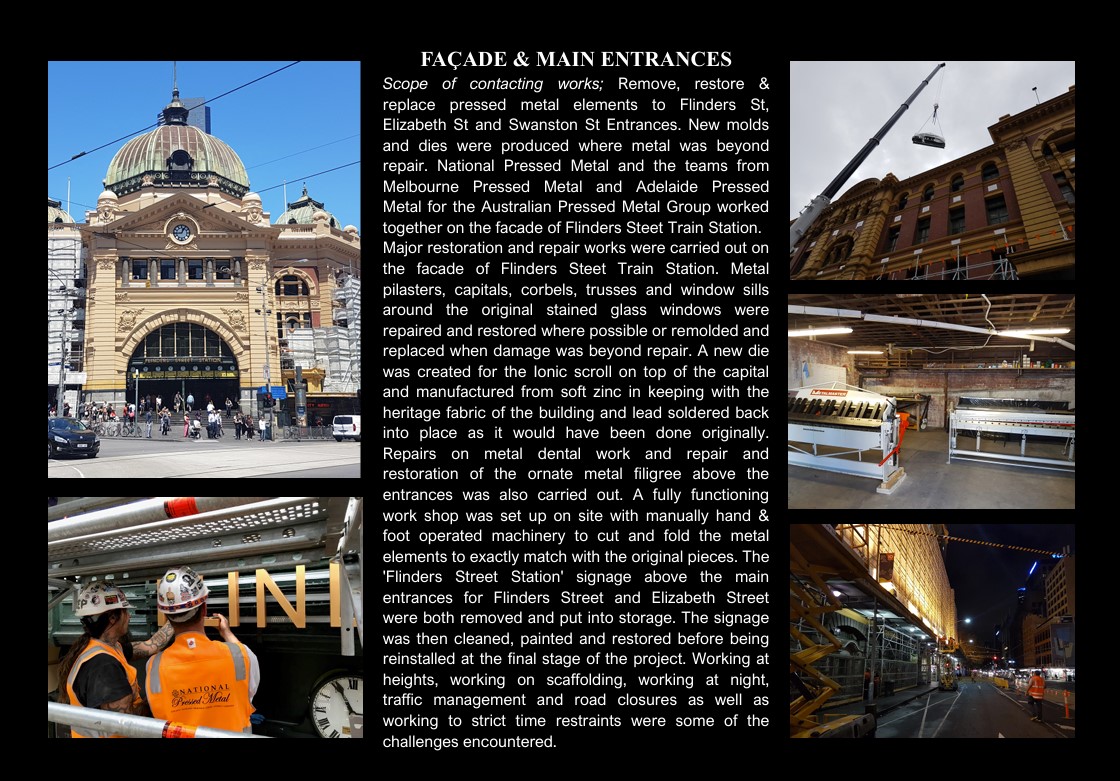

Scope of Contracting WorksRestoration of heritage pressed metal elements to extrerior of Flinders Street Train Station. Main Entrance Facade, Awning facade, Train Platforms incuding heritage lead flashings, Copper Domes and Copper Acroterion's restoration and replication.

-

Project Duration2016 - 2019

-

ClientDevelopment Victoria. Principal Contractor: BUILT. Heritage. Architect: Lovelle Chen

-

Project LocationElizabeth Street & Swanston Street, Melbourne

-

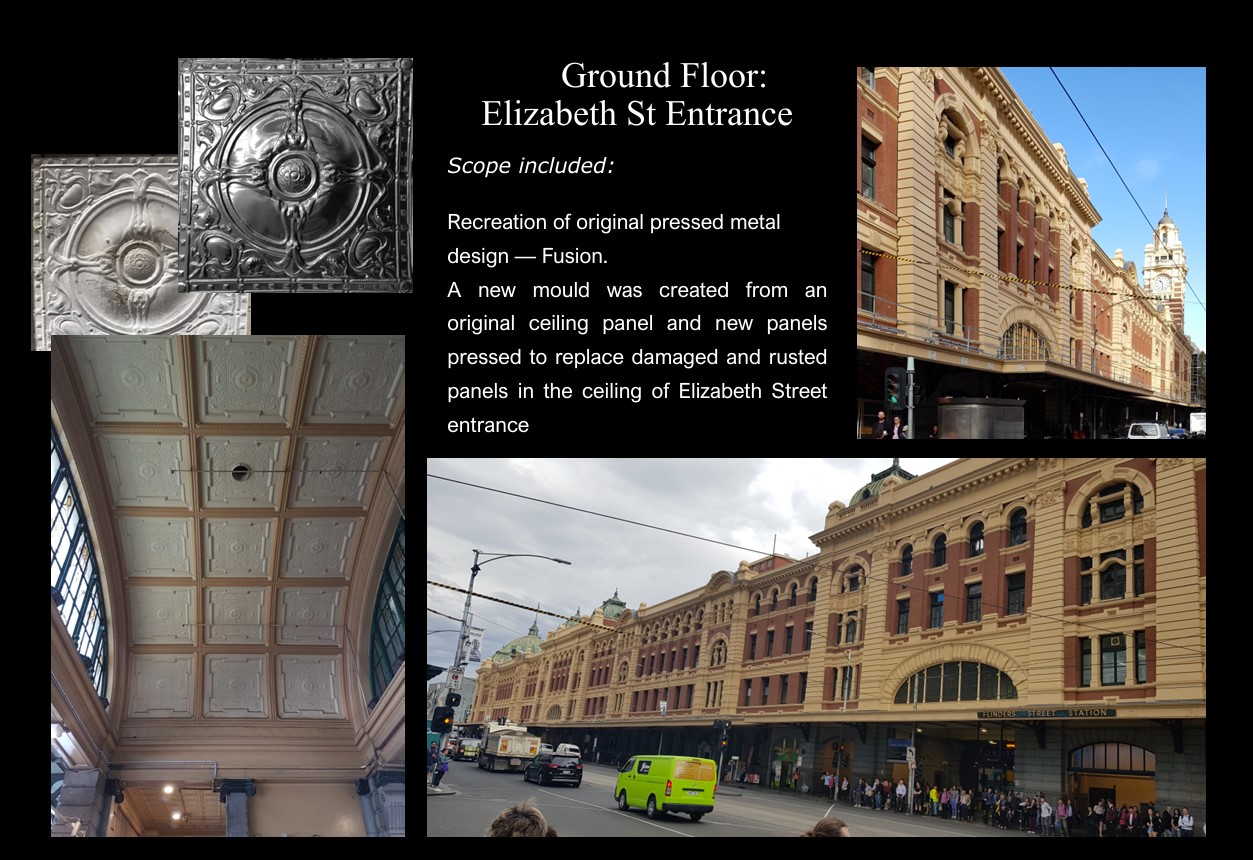

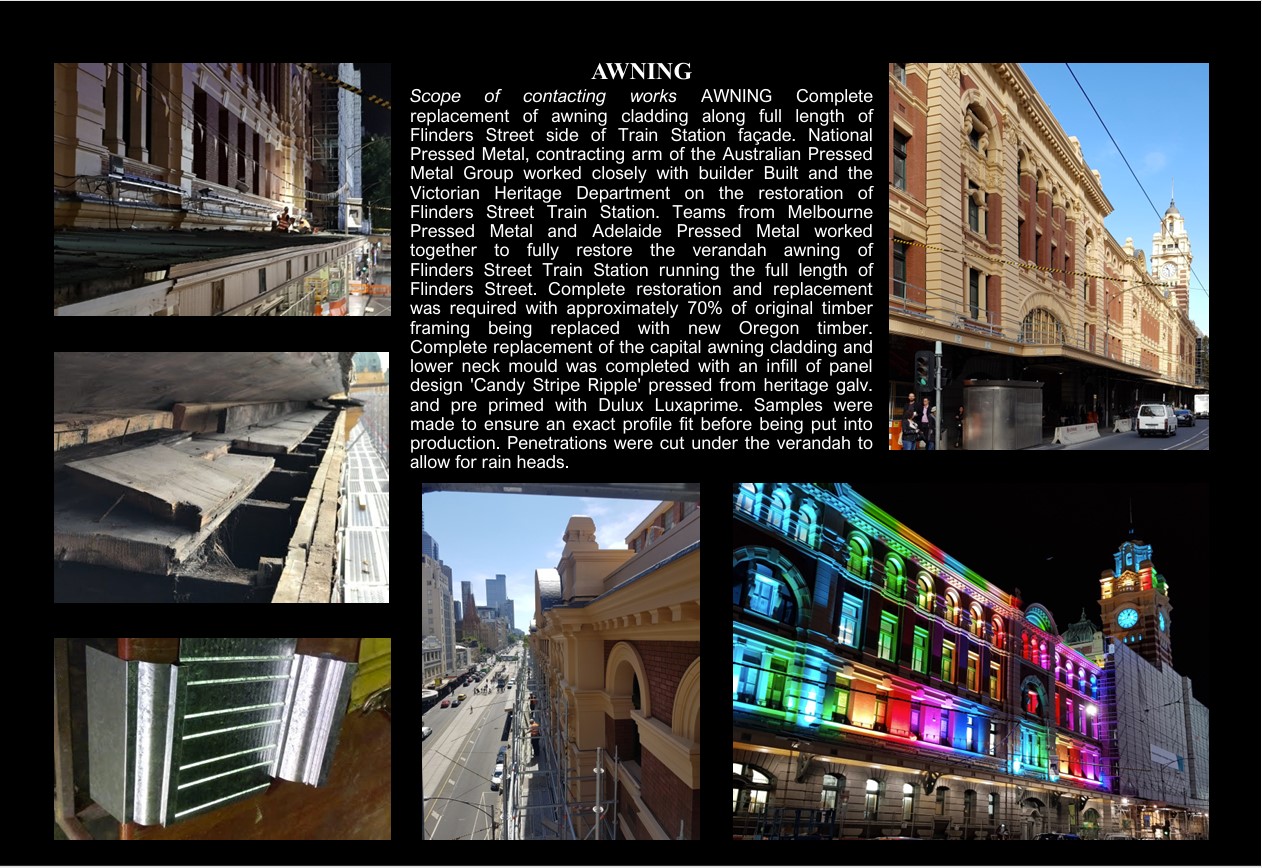

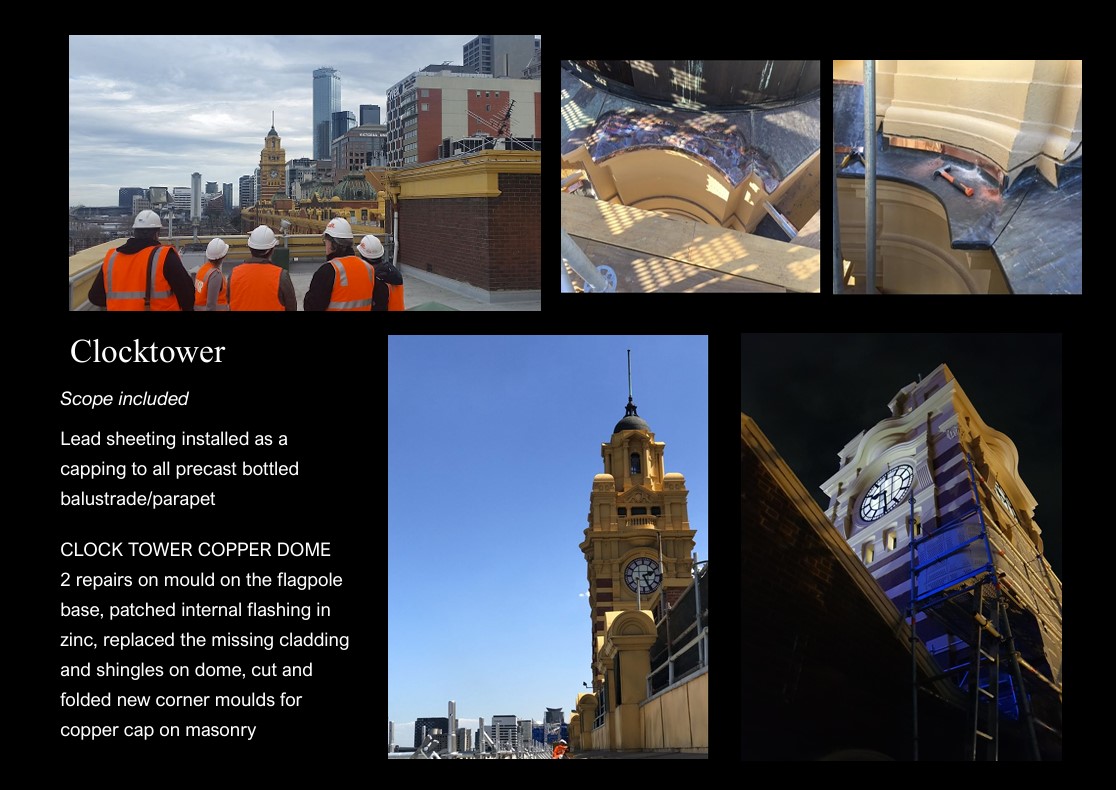

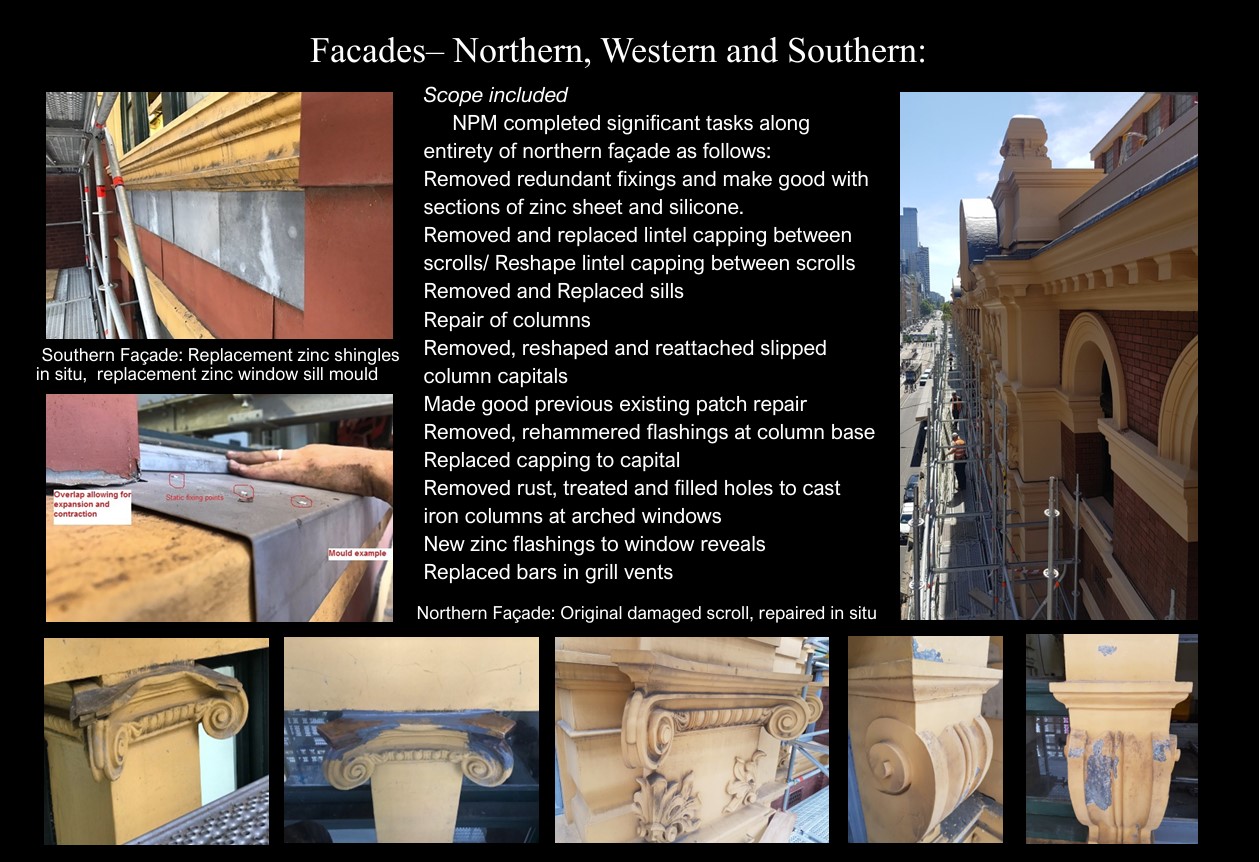

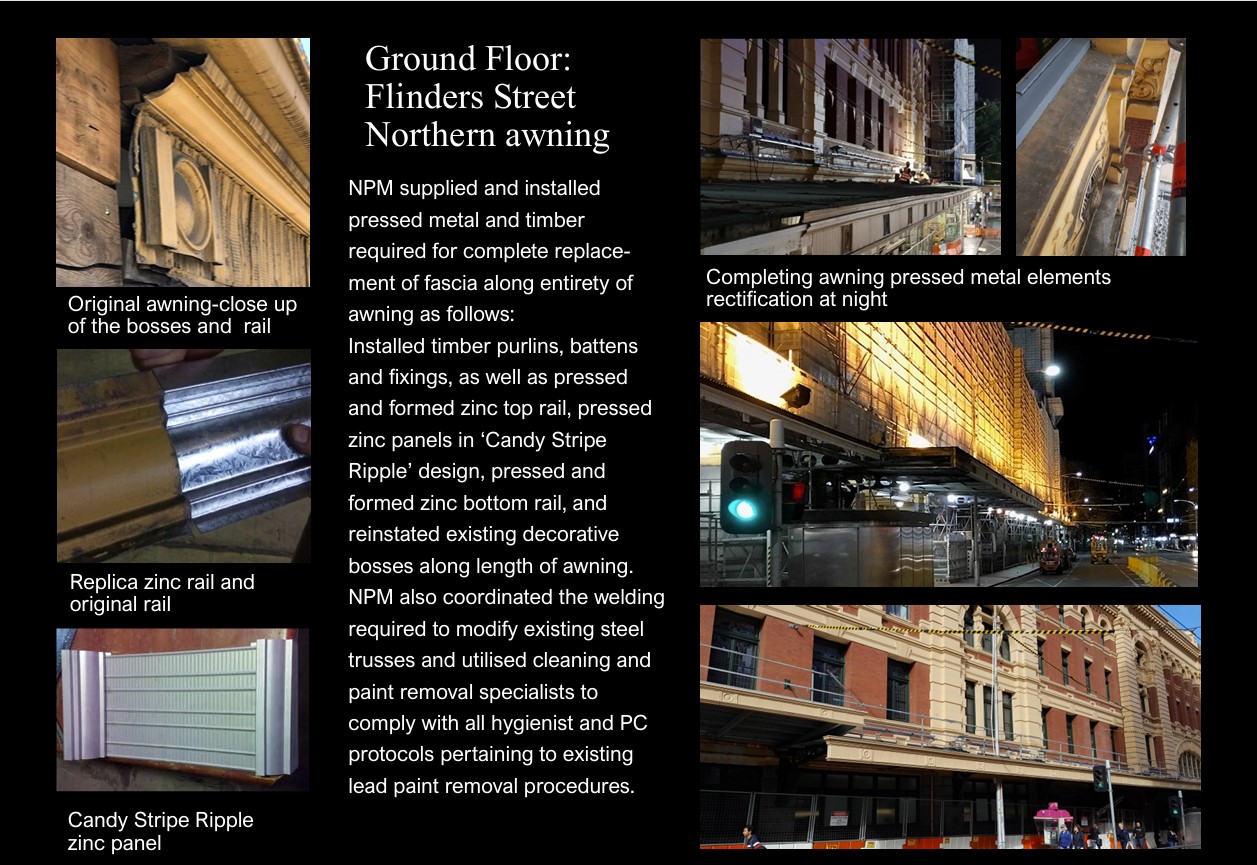

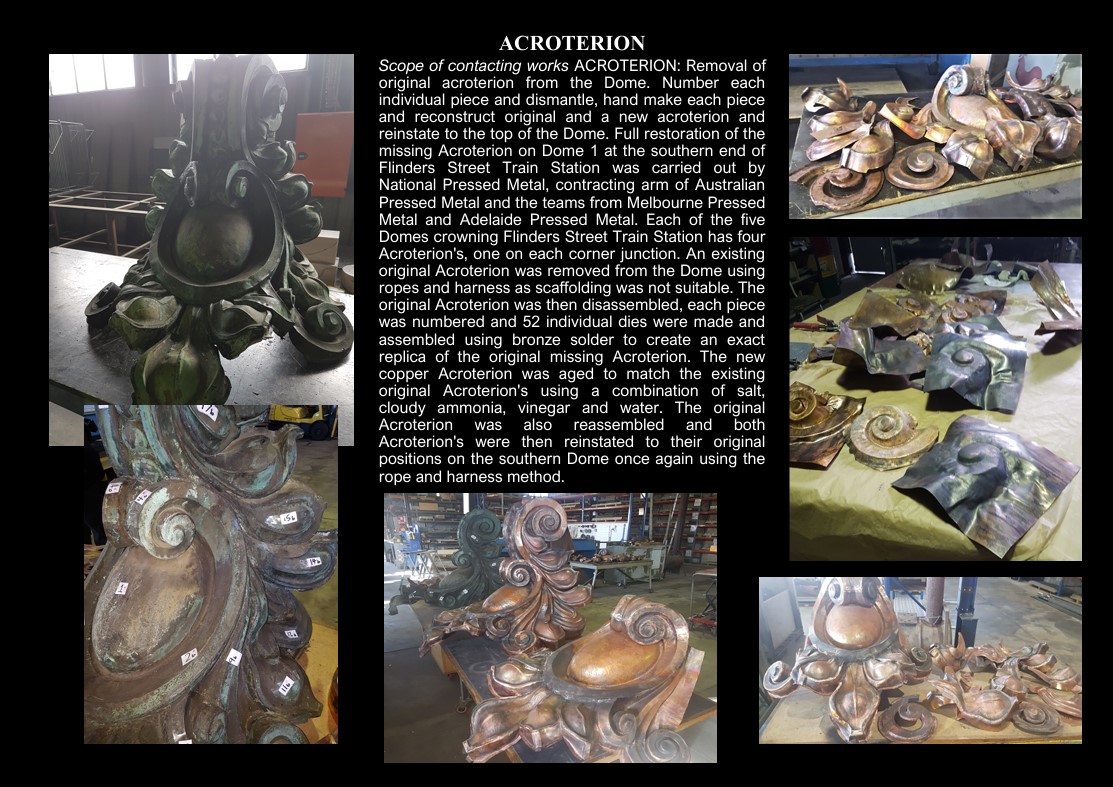

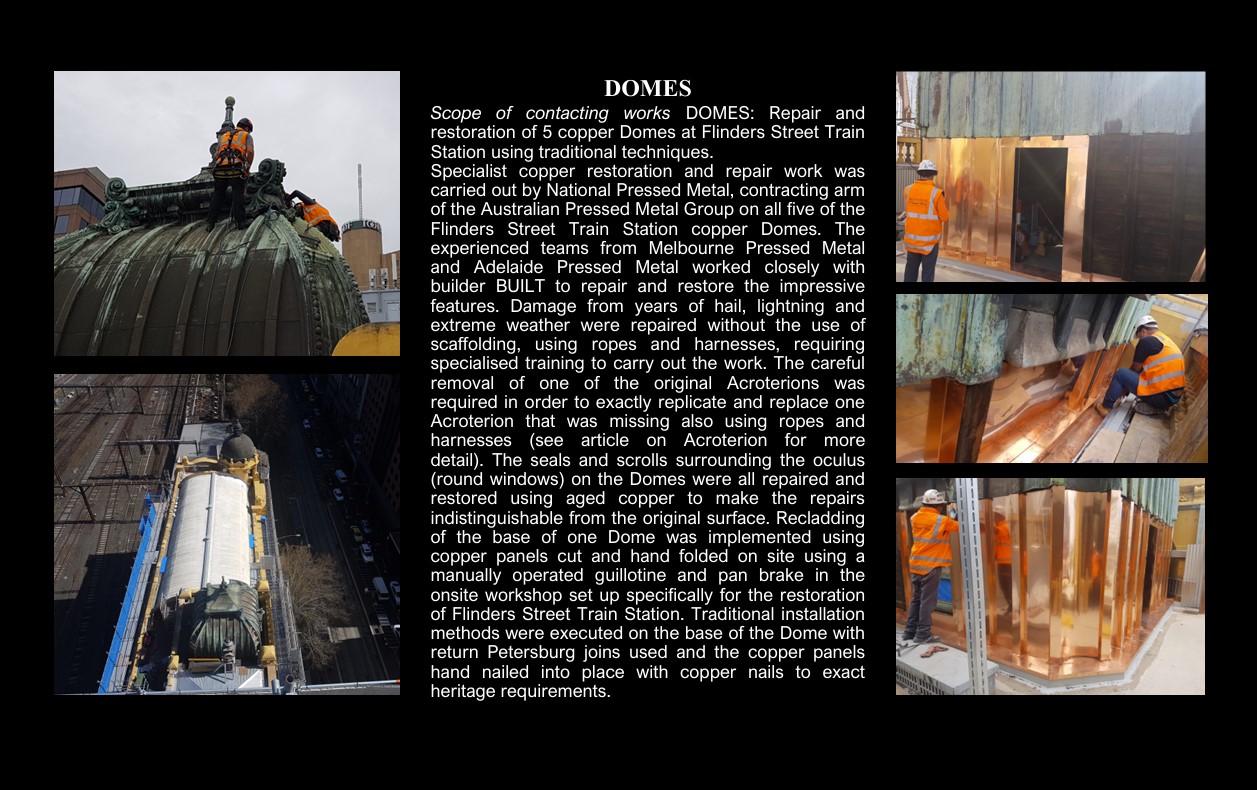

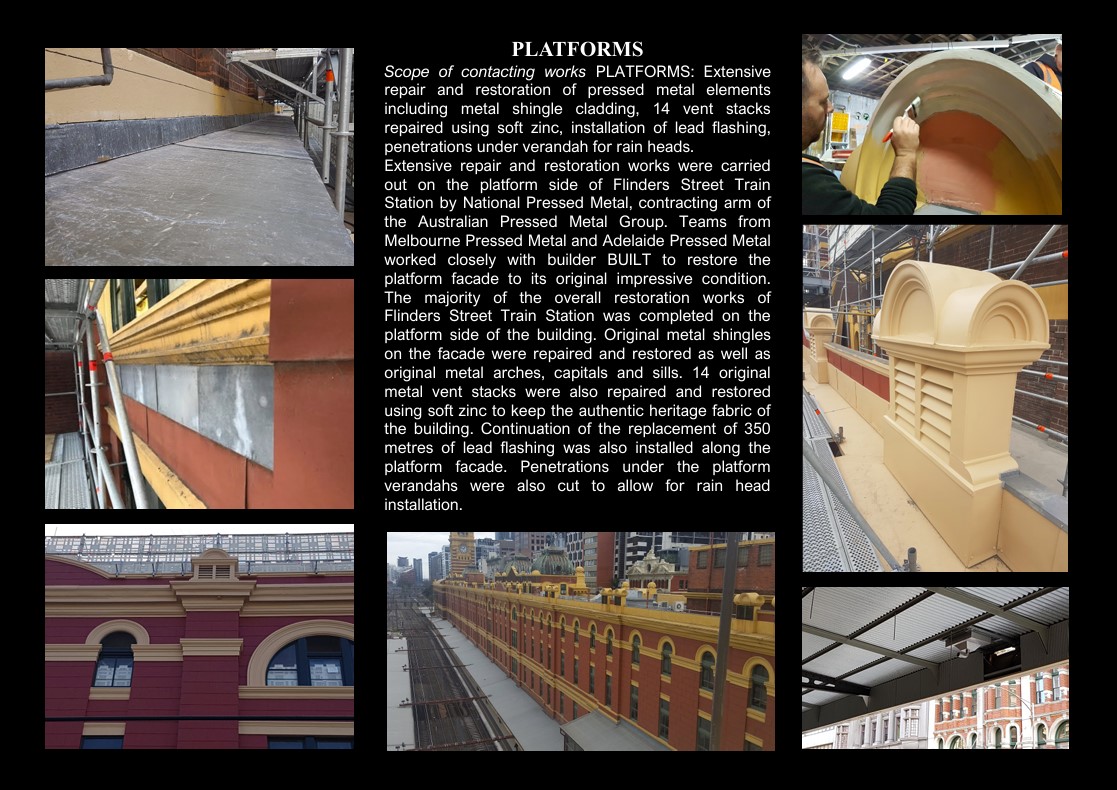

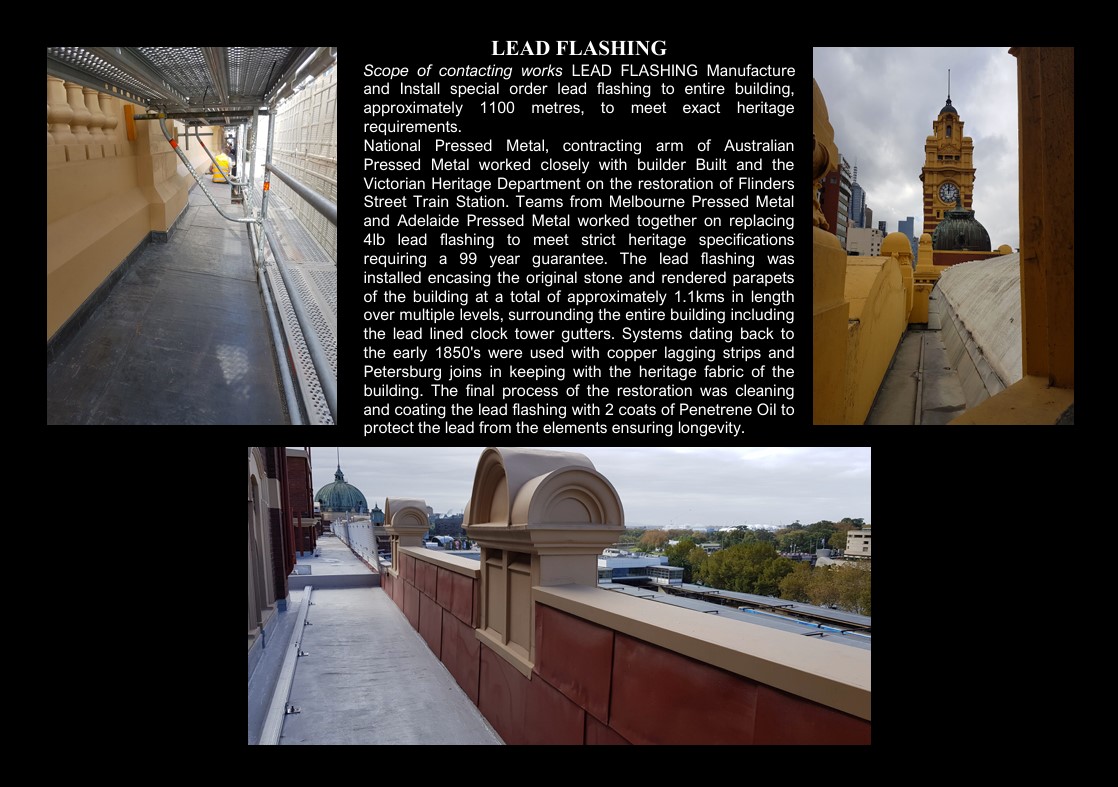

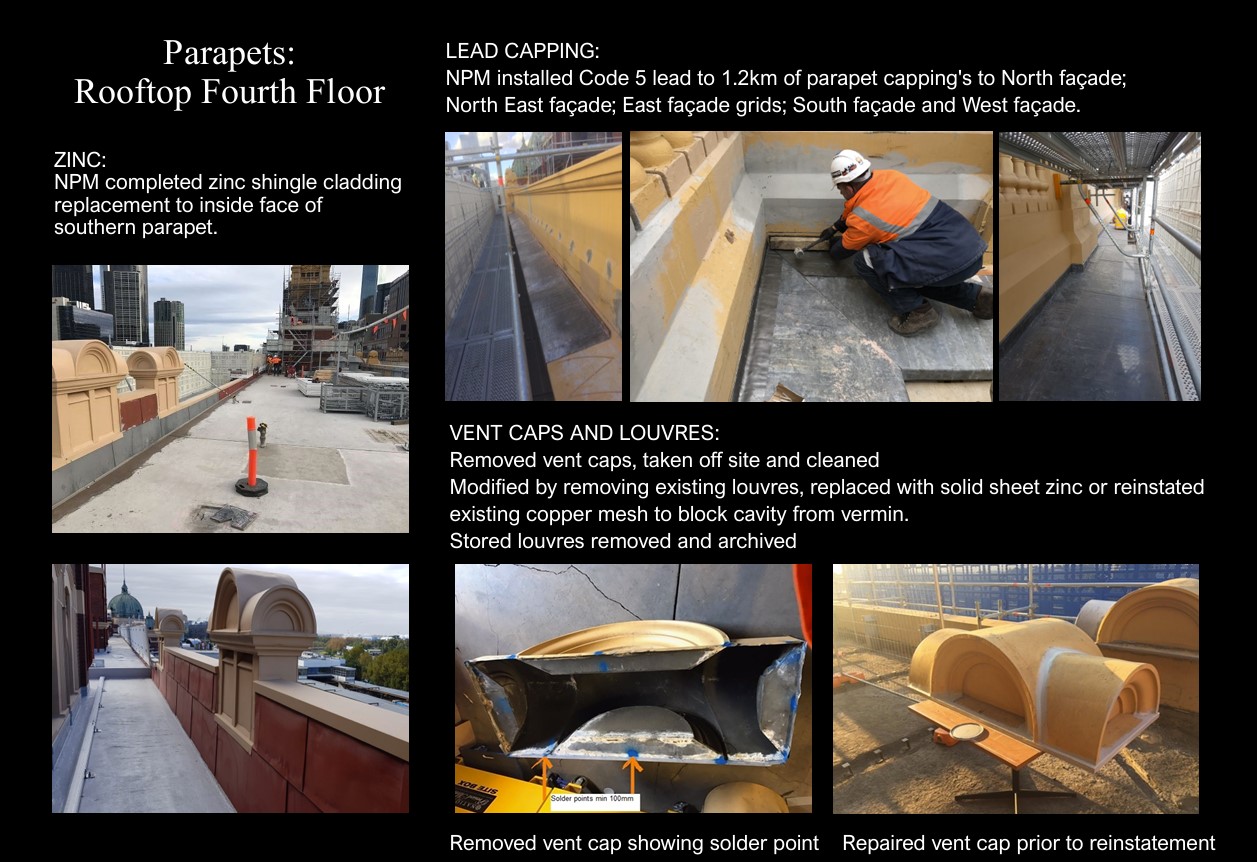

Project DescriptionScope of contracting works: FACADE & MAIN ENTRANCES Major restoration and repair works were carried out on the facade of Flinders Steet Train Station. Metal pillarsters, capitals, corbels, trusses and window sills around the original stained glass windows were repaired and restored where possible or remolded and replaced when damage was beyond repair. A new die was created for the Ionic scroll on top of the capital and manufactured from soft zinc in keeping with the heritage fabric of the building and lead soldered back into place as it would have been done originally. Repairs on metal dental work and repair and restoration of the ornate metal filigree above the entrances was also carried out. A fully functioning work shop was set up on site with manually hand & foot operated machinery to cut and fold the metal elements to exactly match with the original pieces. The 'Flinders Street Station' signage above the main entrances for Flinders Street and Elizabeth Street were both cleaned, painted and restored before being reinstalled at the final stage of the project. Working at heights, working on scaffolding, working at night, traffic management and road closures as well as working to strict time restraints were some of the challenges encountered. AWNING FACADE full restoration of the verandah awning of Flinders Street Train Station running the full length of Flinders Street. Complete restoration and replacement was required with approximately 70% of original timber framing being replaced with new oregon timber. Complete replacement of the capital awning cladding and lower neck mould was completed with an infill of panel design 'Candy Stripe Ripple' pressed from heritage galv and pre primed with Dulux Luxaprime. TRAIN PLATFORMS Extensive repair and restoration works were carried out on the platform side of Flinders Street Train Station to restore the platform fascade to its original impressive condition. Original metal shingles on the facade were repaired and restored as well as original metal arches, capitals and sills. 14 original metal vent stacks were also repaired and restored using soft zinc to keep the authentic heritage fabric of the building. Continuation of the replacement of 350 metres of lead flashing was also installed along the the platform fascade. Penetrations under the platform verandahs were also cut to allow for rain heads installation. LEAD FLASHINGS replacement of 4lb lead flashing to meet strict heritage specifications requiring a 99 year guarantee. The lead fashing was installed encasing the original stone and rendered parapets of the building at a total of approximately 1.1kms in length over multiple levels, surrounding the entire building including the lead lined clock tower gutters. Systems dating back to the early 1850's were used with copper lagging strips and Petersburg joins in keeping with the heritage fabric of the building. The final process of the restoration was cleaning and coating the lead flashing with 2 coats of Penetrene Oil to protect the lead from the elements ensuring longevity. COPPER DOMES Specialist copper restoration and repair work was carried out on all five of the Flinders Street Train Station copper Domes. Damage from years of extreme weather were repaired without the use of scaffolding using ropes and harnesses, requiring specialised training to carry out the work. The careful removal of one of the original Acroterions was required in order to exactly replicate and replace one Acroterion that was missing also using ropes and harnesses. The seals and scrolls surrounding the oculus (round windows) on the Domes were all repaired and restored using aged copper to make the repairs indistinguishable from the original surface. Recladding of the base of one Dome was implemented using copper panels cut and hand folded on site using a manually opeated guillutine and pan brake in the onsite workshop set up specifically for the restoration of Flinders Street Train Station. Traditional installation methods were executed on the base of the Dome with return Petersburg joins used and the copper panels hand nailed into place with copper nails to exact heritage requirements. COPPER ACROTERION Full restoration of the missing Acroterion on Dome 1 at the southern end of Flinders Street Train Station was carried out by National Pressed Metal, contracting arm of Australian Pressed Metal and the teams from Melbourne Pressed Metal and Adelaide Pressed Metal. Each of the five Domes crowning Flinders Street Train Station has four Acroterions, one on each corner junction. An existing original Acroterion was removed from the Dome using ropes and harness as scaffolding was not suitable. The original Acroterion was then disassembled, each piece was numbered and 49 different dies were made and assembled using bronze solder to create an exact replica of the original missing Acroterion. The new copper Acroterion was aged to match the existing original Acroterions using a combination of salt, cloudy ammonia, vinegar and water. The original Acroterion was also reassembed and both Acroterions were then reinstated to their original positions on the southern Dome once again using the rope and harness method.